03-01 2023

0 CommentsWhat distinguishes gold foiling from gold silk-screening?

When it comes to producing gold logos, elements or lettering, screen printing and foiling are among the most popular methods used for packaging design. The main visual difference between them is that one of these technologies gives a subtle shine, while the other gives an almost mirror-like effect. Both methods have been around for a long time, so you've no doubt seen packaging with both methods when you're walking around shops and supermarkets. Not only do they differ in appearance, but also in production technology, so it is useful to know which of these technologies is superior.

The silk-screen printing of gold logos is applied using a thin, silk-like fabric mesh stretched over a frame. The fabric mesh must be prepared such that the ink will only travel through the image of the logo or other graphic element superimposed on the mesh. The grid is now ready, and the product is fastened to it while ink is swiped through it and imprinted onto the box. Silkscreen gold is extracted for printing using gold inks containing small shiny particles. Its faint sheen is caused by these particles.

Advantages of silk-screen gold:

1) When gold logos are screen-printed, the printing surface is not pressed. For direct printing on corrugated cardboard packaging with a smooth surface, this makes the method perfect.

2) It is possible to produce quite fine lines.

3) Due to the opaque and very opaque nature of gold screen printing inks, they print wonderfully on coloured surfaces. This is one of the colours we recommend when placing your logo on black corrugated boxes.

4) The gold paint adheres firmly to the surface, without rubbing or scratching.

5) Applying the print on a few boxes is relatively affordable because the cost of creating the adhesives for this technique is modest.

Disadvantages of silk-screen gold:

1) Not as bright as gold foil.

2) Not suitable for large print areas.

3) Not usually effective on textures-heavy surfaces (e.g. velvet).

With the use of a metallic adhesive especially created to print the desired logo or graphic element, gold foiled logos are affixed to the box's surface. The cliché is inserted into the special equipment and heated, with the product placed underneath it. The product and the hot metal adhesive must be sandwiched by a thin gold foiling sheet, which must then be pushed firmly against the product. The foiling film is clamped and adhered to the product at the proper locations by the design components that are elevated in the adhesive. The end result is a flawless, glossy, almost mirror-like image.

Benefits of gold foiling:

1) High-gloss surface of the printed elements.

2) Environmentally friendly printing process (no inks, thinners, etc.).

3) Due to the foil's opacity, it shines brilliantly on coloured surfaces.

4) It is possible to produce quite fine lines.

5) Excellent application on strongly textured surfaces.

Disadvantages of gold foiling:

1) Not suitable for printing directly onto corrugated board, as it causes the corrugated surface to buckle and split.

2) It is necessary to use metal clips, which are expensive to produce.

3) Not appropriate for huge print runs since the price of clichés and printing skyrockets as the run size rises.

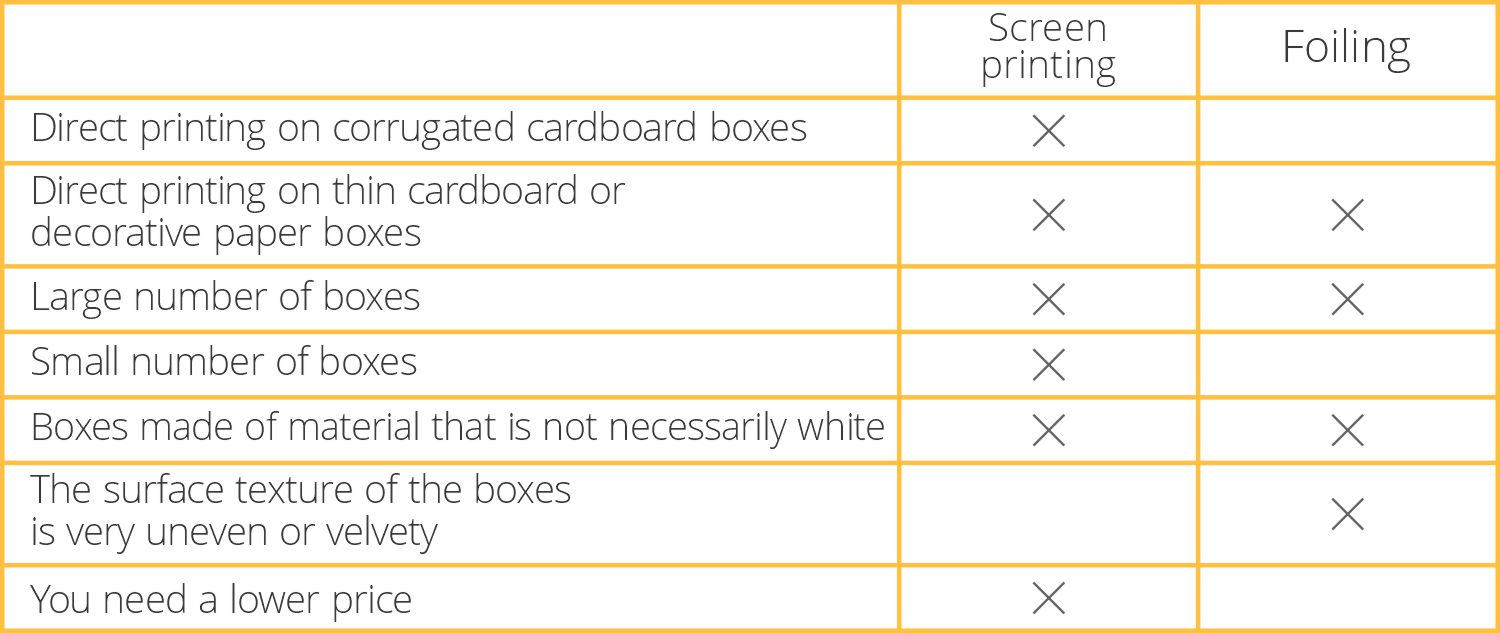

When is which technology appropriate?

Packages with a gold silk-screen logo can be purchased by selecting a single print colour and specifying in the order comments that the print colour must be gold.

If you want a foiled gold logo on corrugated cardboard packaging, we offer an indirect (lamination) stamp, but we only do lamination with foiling for special orders of 500 and up.

All content published on this site is the exclusive property of UAB SUPERBOX. Any partial and/or total reproduction of the website SUPERBOX is strictly prohibited without the prior written consent of UAB SUPERBOX.